At Champion, we test our products to destruction to ensure they offer the highest level of protection for equestrians. All our riding hats and body protectors meet the current testing standards and carry the quality symbols you’d expect. Learn all about how we test our products to provide unrivalled quality and safety that you can trust.

For the second year in a row, our Champion helmets have taken the #1 spot on the Virginia Tech Helmet Ratings. Not only that, but they hold the top 5 rankings!

The Purpose of Riding Helmets

Wearing a riding hat can not only protect you against short-term injury, but it can also significantly reduce the risk of long-term issues.

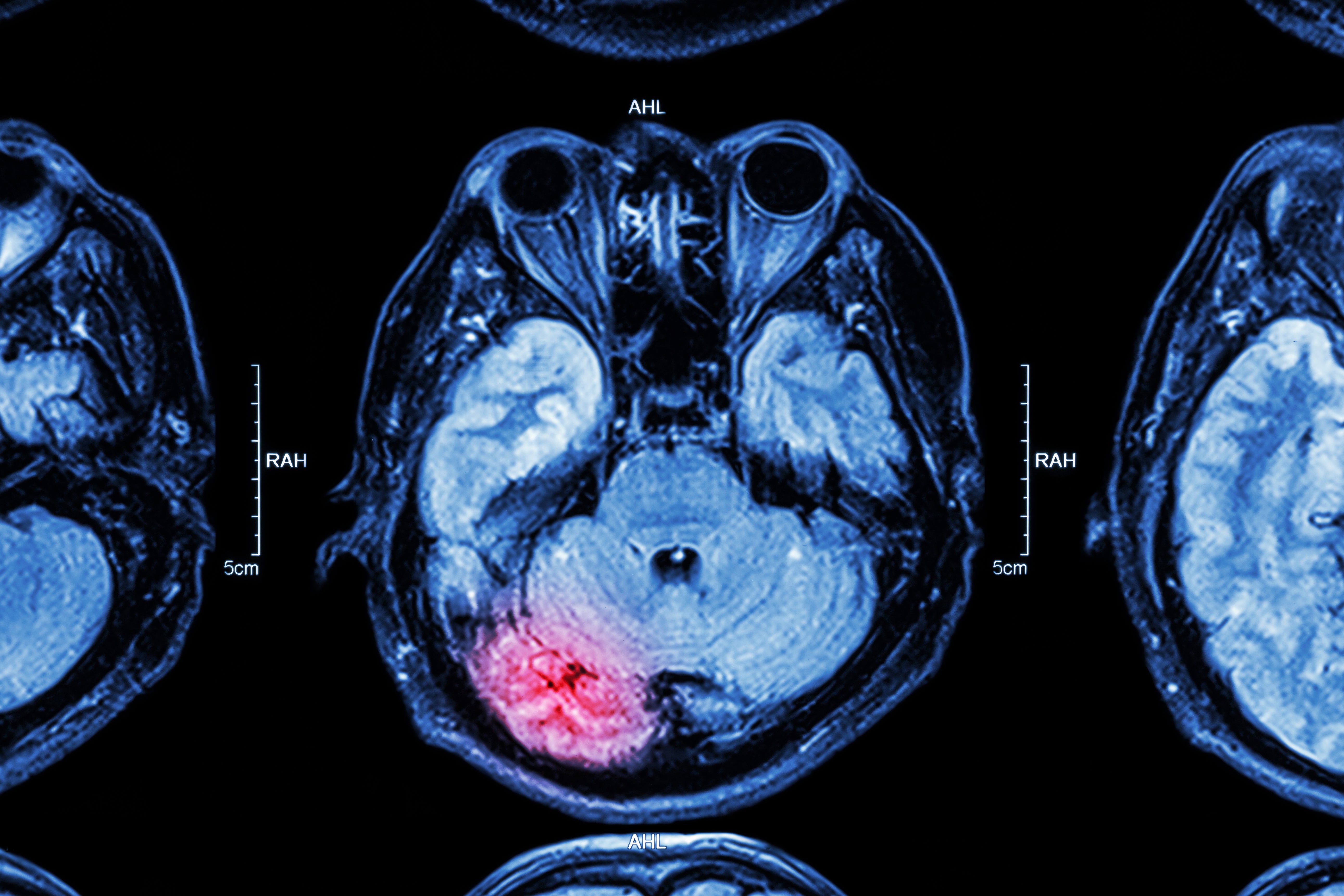

The danger of impacts to the head

Let’s talk about head health. Each year, millions are invested into research concerning the brain and both the long- and short-term effects of impacts to the head. Current research suggests there’s a link between head impacts and dementia and Alzheimer’s, as well as CTE (Chronic Traumatic Encephalopathy), a condition where multiple head impacts damage brain tissues. Impacts to the head can also result in persistent post-concussion syndrome (PPCS) which is where concussion symptoms remain for an extended period and can even be lifelong.

Riding helmets and impact

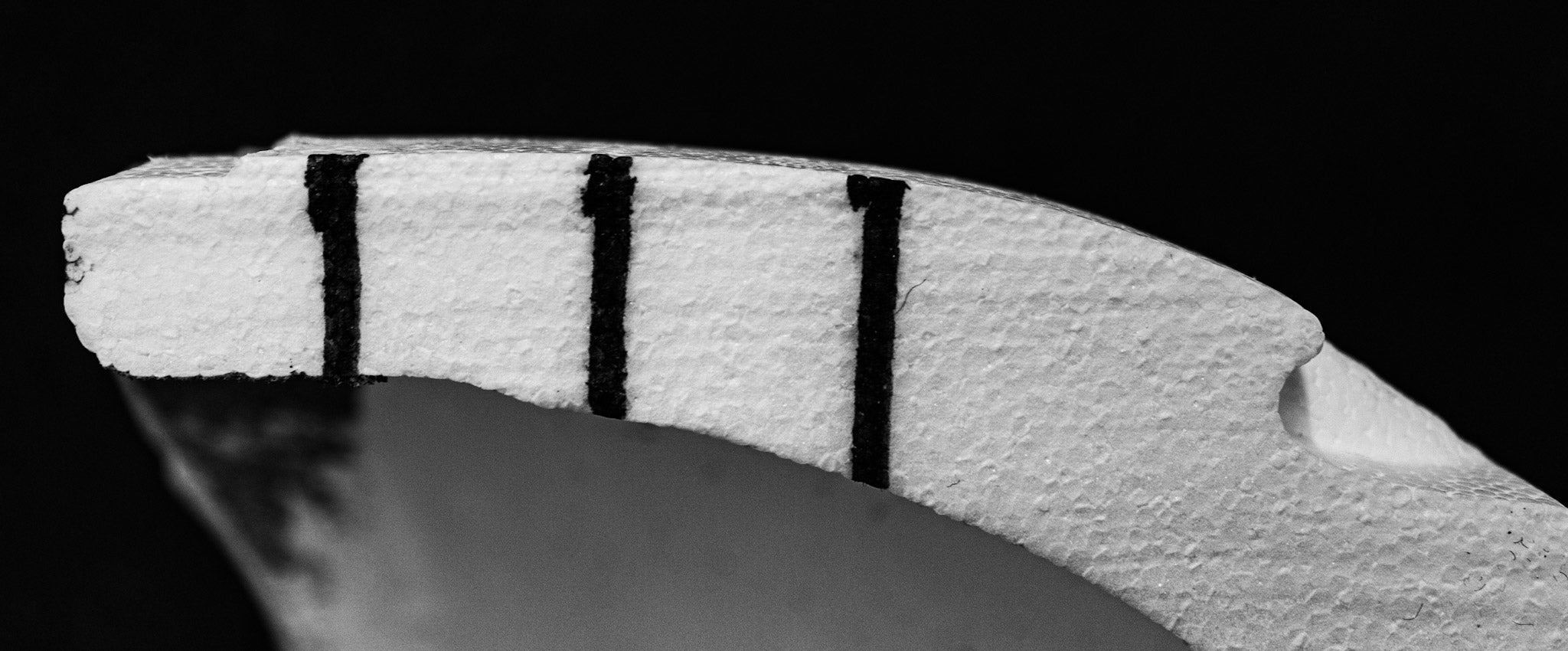

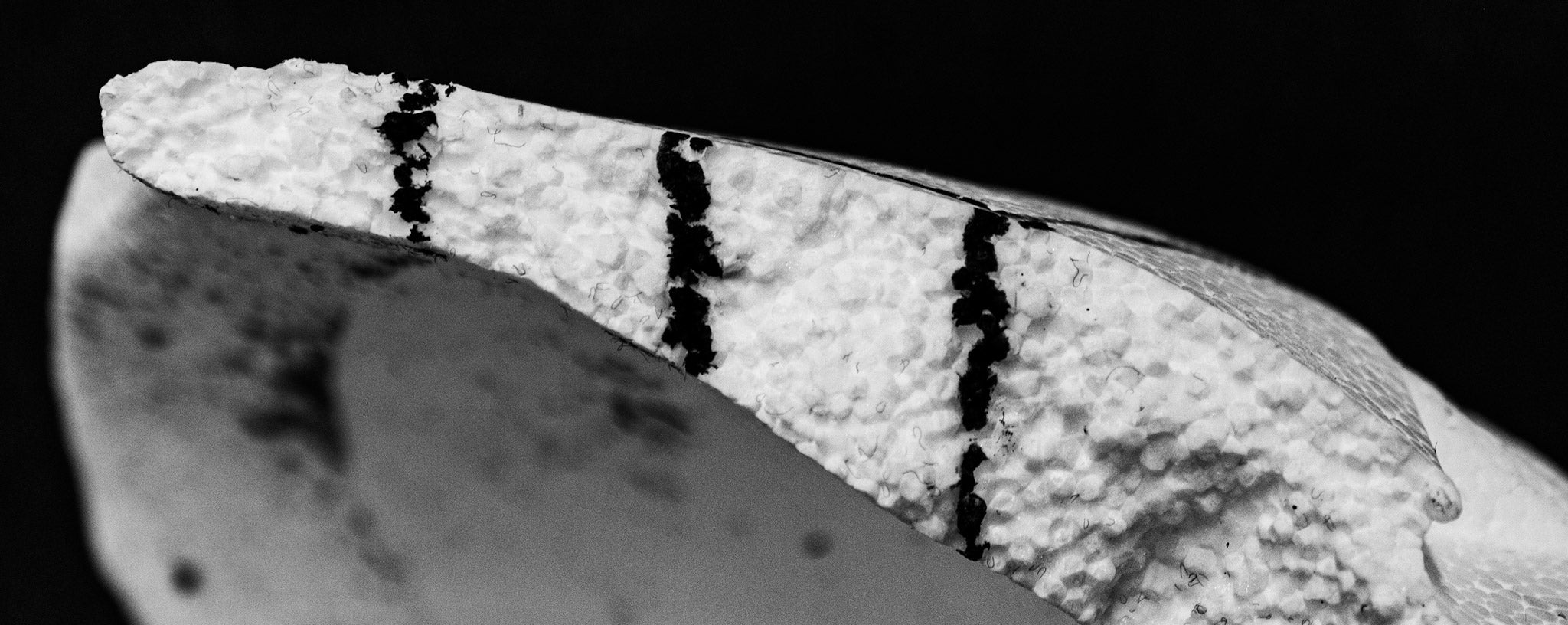

We all know the risk. That’s why we make PPE to manage the risk of the activity. However, it’s important to note that equestrian helmets are a one-time impact, once it’s done, it’s job done. Every time you have an impact, it’s time to replace your helmet. Even if it looks fine from its exterior, the foam inside could be compromised.

Before

After

Quality Symbols

When buying a riding hat, we recommend only purchasing one that carries the current quality symbols as this demonstrates the product’s reliability, safety, and quality.

Type testing to a standard provides the use of the CE/UKCA mark, this requires full testing of four helmets per year to maintain this license and also allows them to be sold to Europe. Additionally, all helmets should carry the registered trademark of the British Standards Institute (BSI), this ensures the hat has been independently tested and meets the current standard in the UK.

At Champion, we submit six samples from production batches of 1600 and only allow helmets to be released for sale when test reports have been returned.

Riding Hat Safety Standards

There are currently five riding hat safety standards, these are as follows:

EN1384:2023

EN1384:2023 is a new European standard for equestrian helmets with increased safety requirements compared to previous standards, including new performance tests and higher shock absorption and mechanical strength requirements.

PAS015:2011

This is a high-level standard for Europe and requires more demanding testing than VG1 and ASTM F1163. All Champion riding helmets are made to this standard.

VG1 01.040

The European standards 1384:2012 were withdrawn in November 2014 and replaced by VG1 01.040. Champion helmets meet this standard through testing to PAS015.

Snell E2021 (US)

Snell is one of the most ‘extreme’ testing standards. The standard requires height and crush tests much higher than PAS015 and often involves a drop onto a metal ball instead of a sharp metal edge. Our Pro Ultimate Jockey Helmet currently meets this standard.

ASTM F1163-15

This is one of the least strict riding hat standards available. It requires no spike or crush test and allows up to 300g in impact response. Our helmets easily pass this due to testing for the other required standards and we test annually to meet requirements to be able to sell in America.

How We Test Our Helmets

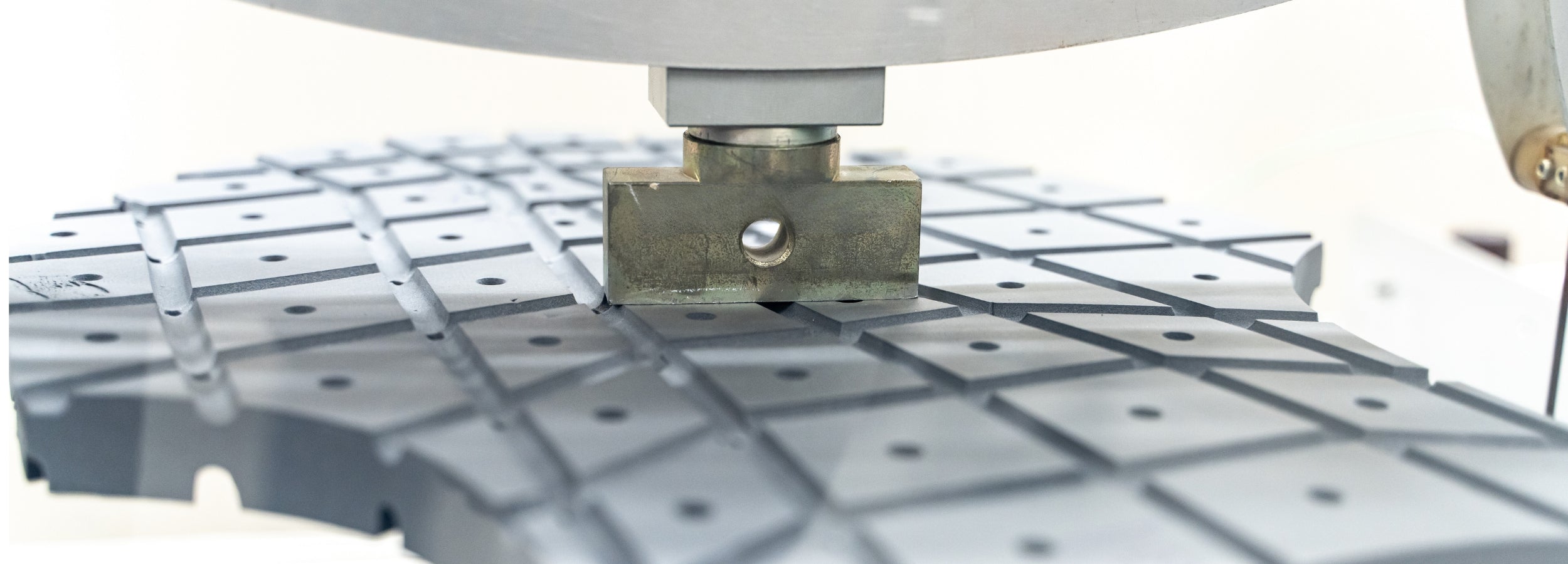

IMPACT

A helmet is dropped from a set height onto set anvils (each standard has different anvils).

LATERAL DEFAMATION

The helmet is then tested sideways in case a horse lands on you.

RETENTION STRENTH

A force is pulled on the chin strap.

RETENTION STABILITY

Static load to test if the helmet moves at all. Or a pull-off test is carried out with a violent load to see if it comes off the head.

CONDITIONING

Tests if the helmet works in extreme cold, heat and wet (e.g. PAS0 -20deg, +50, water test).

PENETRATION TEST

Checks that the helmet can stop a spike from penetrating the head, dropped from various heights 50cm – 100cm depending on the standard.

Body protectors & Safety

As a company, we would say ideally you should wear a body protector every time you ride. It’s doing the same job for your ribs and torso as a helmet is doing for your head. If you’re looking to buy a body protector, it’s a little more straightforward as you just have to look out for the BETA tag.

BETA Scheme

The BETA scheme covers three levels, each designed for different activities:

- Level 1: this is the lowest level of protection and is suitable for professional jockeys only. It’s very lightweight and designed to meet weight restrictions.

- Level 2: this is a lower level of protection and is suitable for general riding in low-risk situations and professionals such as licensed jockeys.

- Level 3: the highest level and considered appropriate for general riding activities. This is a requirement for any cross-country competitors. Both our Ti22 and Liber8 meet this standard.

EN13158:2018 standard

There is currently one standard for static garments, EN13158:2018. This assesses impact and protective coverage, as well as taking into consideration comfort and fit elements.